Smooth surface finish with no visible layer lines

SLA (Stereolithography) produces parts from liquid resins that are cured and solidified by UV light. SLA offers a variety of materials that are designed simulate standard engineering plastics. Because of its short layer heights and high tolerances, SLA can produce parts with complex internal and external geometries. SLA is also great for small, highly detailed models. Parts have a smooth surface finish, making stereolithography ideal for cosmetic prototypes.

Contact us now.

Smooth Surface Finish

SLA parts have a smooth surface finish, comparable to injection molded parts, making SLA ideal for fit testing and aesthetic evaluation.

High Detail

Small layer heights, high resolution and high geometric stability make stereolithography ideal for small, detailed parts.

Material Selection

Stereolithography offers a broad selection of materials designed to emulate standard production materials such as ABS, polycarbonate and polypropylene and clear plastic.

Standard White

The ABS plastic like nature of this material makes it ideal for snap-fit parts and casings. It is easily integrated in production cycles to test designs ensuring proper functionality of parts before they are launched into full production — providing customers the opportunity to get to market quickly.

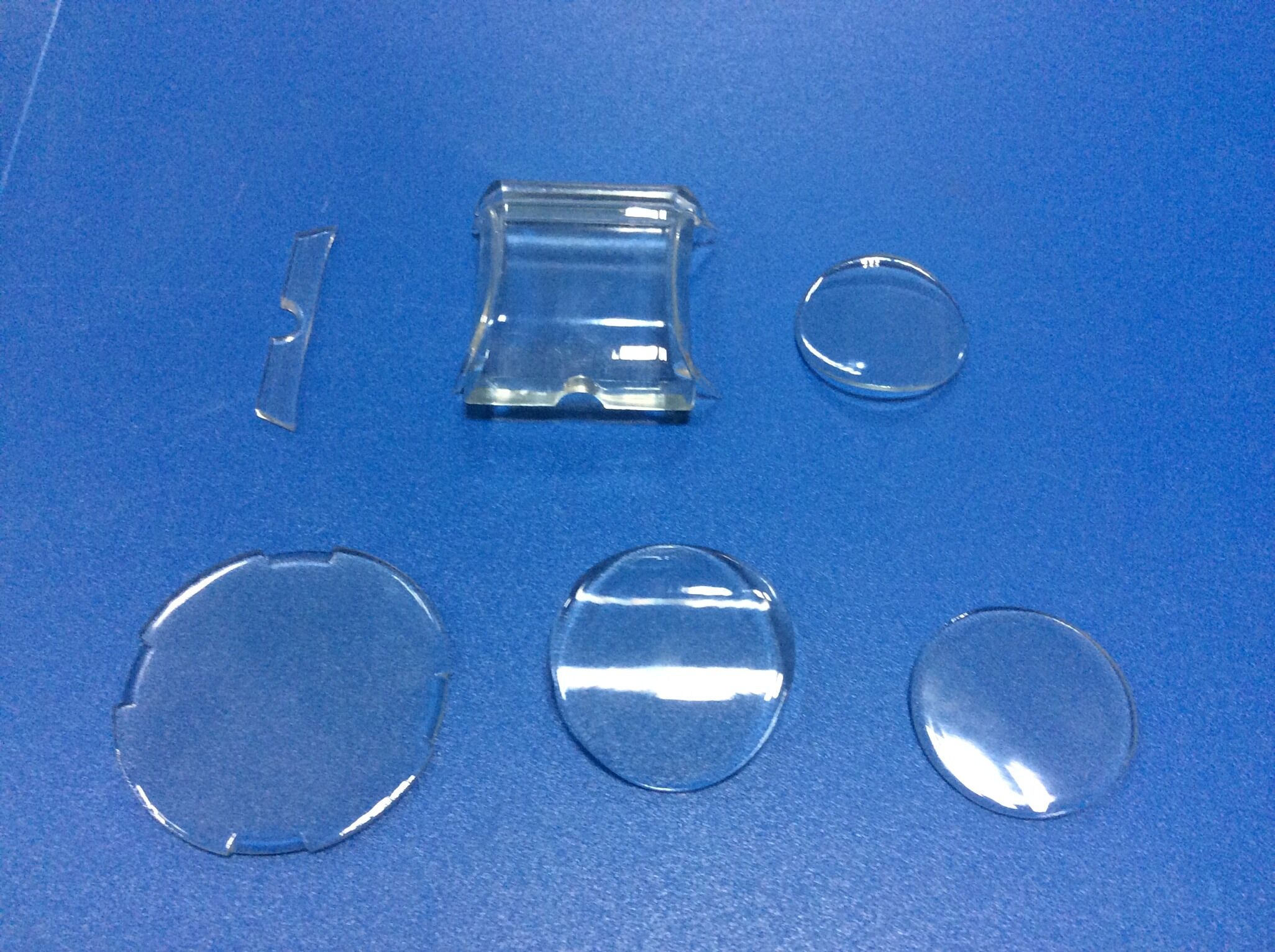

Clear plastic

Transparent materials can be polished to an optical-grade finish. Great for simulating glass parts.

Durable plastic

Durable material is ideal for the production of tough, complex parts that also exhibit excellent moisture and thermal resistance, which produces very accurate parts with high feature resolution.

Stereolithography Applications

Cosmetic Prototypes

Fit Testing